Expert guidance, ready-to-use tools, and hands-on support for organisations who need big results without big overheads.

ABN 62 113 839 328

About

LeathFleet Advisory provides specialist fleet management solutions tailored for government, council, and small-to-medium organisations across Australia. Drawing on deep experience managing large and complex fleets, we help clients reduce costs, improve safety, and optimise asset lifecycles.

LeathFleet Advisory combines technical expertise with a practical, hands-on approach. Our goal is simple: to make fleet management easier, safer, and more cost-effective for every client.

With more than a decade of senior-level fleet and asset management experience in complex government environments, our founder has led large-scale programs that cover thousands of vehicles and multi-million-dollar budgets. This background includes designing and implementing fleet strategies, capital replacement plans, compliance frameworks, and advanced data analytics for some of Australia’s most challenging operational landscapes. That hands-on expertise now underpins every service we provide, giving clients the assurance that their fleet is guided by proven, real-world leadership.

Services

Fleet Strategy & Policy Development

LeathFleet Advisory develops comprehensive fleet management strategies tailored to your organisation’s goals and compliance obligations. Services include:

Drafting or updating fleet management policies that align with ISO 55000 asset management principles and government standards.

Creating detailed asset lifecycle plans covering acquisition, operation, maintenance, and end-of-life disposal.

Designing governance frameworks that clarify roles, responsibilities, and reporting lines for fleet operations.

Providing a 5–7 page strategic fleet report highlighting key risks, priorities, and opportunities, written from an expert’s perspective: “What I’d do in your shoes.”

Offering practical guidance on policy implementation, change management, and staff training to ensure organisation-wide adoption.

Capital Planning & Procurement

We deliver data-driven capital programs that keep your fleet modern, cost-effective, and fit for purpose.

Development of 10-year fleet replacement programs using advanced modelling to forecast costs and timing.

Whole-of-life cost modelling to reveal the total financial impact of assets, from acquisition to disposal.

Procurement pack preparation, including fit-out specifications, accessory guides, and cost comparison models, to help you secure best-value outcomes.

Optional Light Fleet Specification & Standardisation Kits, including customised specification documents and a “How to Use Your Standard Vehicle Specification Pack” guide.

Advice on leveraging supplier contracts, fleet leasing options, and market pricing to optimise capital spend.

Data & Reporting Solutions

We turn raw fleet data into actionable insights for confident decision-making.

Detailed fleet utilisation snapshots and reporting that clearly identify under-utilised assets, including editable Excel tools and user guides so your team can update data over time.

Key performance indicator (KPI) development and automated reporting for cost, fuel, maintenance, and compliance metrics.

Comprehensive replacement planning reports, complete with Excel models and one-page executive summaries.

Customised visualisations and board-level reporting that highlight savings opportunities and track strategic goals.

Contact

Whether you need a full fleet strategy, a targeted review, or simply have a question about how we can help, we’d love to hear from you.

Use the form to tell us a little about your organisation and the support you’re looking for. We’ll respond promptly and work with you to find the best fleet management solution.Your details are kept confidential and used only to respond to your enquiry.

Thank you for contacting LeathFleet Advisory. Your message has been received and we will get back to you within 2 business days.

Resources

What Is Fleet Management and Why It Matters

What is Fleet Management?

Fleet management is the coordinated process of acquiring, operating, maintaining, and eventually replacing a group of vehicles or plant assets so they remain safe, cost-effective, and fit for purpose. Whether an organisation owns a handful of vehicles or thousands of trucks and machines, fleet management provides the structure to keep every asset working efficiently.At its core, fleet management covers the entire asset lifecycle, from specification and procurement through maintenance, utilisation monitoring, and end-of-life disposal. Organisations that treat these steps as a single integrated system consistently outperform those that manage each stage in isolation.

Why Fleet Management Matters to Every Organisation

Safety and compliance: Vehicles are workplaces on wheels. Regular servicing, defect reporting, and record-keeping keep employees and the public safe while satisfying legal obligations such as road-worthiness and chain-of-responsibility requirements.

Cost control and budgeting: Fuel, maintenance, and depreciation often rank among the largest operating expenses for councils, government agencies, and businesses. Structured fleet management captures these costs and highlights savings opportunities.

Operational efficiency: A well-run fleet supports staff productivity. When vehicles are available, reliable, and suited to the job, field teams spend less time dealing with breakdowns or scheduling conflicts.

Risk reduction: From accidents to unexpected repairs, unmanaged fleets carry financial and reputational risks. Strategic management reduces these exposures and protects organisational credibility.

The Hidden Costs of Neglecting Fleet Management

Without a structured program, fleets drift toward “run to failure.” Assets are kept too long, repairs grow expensive, and downtime interrupts service delivery. Insurance premiums rise with every preventable incident. Fuel consumption climbs as vehicles age. These hidden costs can exceed the expense of a dedicated fleet strategy.

Modern Best Practices

Data and telematics: GPS tracking, automated service alerts, and real-time utilisation data provide insight well beyond paper logs.

Lifecycle planning: Ten-year replacement programs smooth capital spend and prevent sudden budget shocks.

Standardised specifications: Clear fit-out standards reduce ordering errors and simplify maintenance.

Getting Started

Even small organisations benefit from basic steps:

Create a written fleet policy that sets out driver responsibilities, maintenance schedules, and safety checks.

Track key metrics such as total cost of ownership and utilisation rates.

Develop a replacement plan that forecasts capital needs several years ahead.

Fleet management is not just for large agencies. Any organisation operating vehicles can lower costs and reduce risk by treating its fleet as a strategic asset.

LeathFleet Advisory can help you build the strategy, policies, and data systems to get there

Understanding Fleet Utilisation

How to Measure It and Why It Drives Savings

What Is Fleet Utilisation?

Fleet utilisation is the measurement of how effectively your vehicles are used compared to their availability or intended purpose. High utilisation indicates that vehicles are earning their keep; low utilisation reveals capital tied up in under-used assets.Organisations typically measure utilisation in kilometres travelled, engine hours, or percentage of available time. For example, a vehicle that is available 40 hours a week but driven only 10 hours has a utilisation rate of 25 percent.

Why Fleet Utilisation Matters

Capital efficiency: Vehicles are expensive assets. Every under-used vehicle represents money invested but not generating value.

Lower operating costs: Fewer vehicles mean lower insurance, registration, and maintenance expenses.

Environmental benefits: Reducing fleet size cuts emissions and supports sustainability targets.

When utilisation is tracked and acted upon, organisations can right-size their fleets, keeping enough vehicles to meet demand without paying for unnecessary capacity.

How to Measure Fleet Utilisation

Collect reliable data

Odometer readings or engine-hour meters are the simplest inputs. GPS or telematics systems provide automated and highly accurate usage data. Alternatively, data can be sourced from fuel card data and reports.

Define the measurement unit

Choose the metric that best reflects how vehicles create value: kilometres for road fleets, engine hours for plant and equipment, or percentage of available time for pool vehicles.

Establish benchmarks

Compare results to industry standards or develop internal benchmarks based on job requirements.

Analyse patterns

Look for vehicles with consistently low usage across months or seasons, and identify duplicates performing similar tasks in the same location.

Acting on the Results

Reallocate or pool vehicles where demand is intermittent.

Downsize the fleet by disposing of surplus assets and redirecting funds to high-value areas.

Adjust maintenance schedules to match actual use, reducing unnecessary servicing.

The key is to treat utilisation data as a decision-making tool, not just a report. An evidence-based downsizing can release significant capital while maintaining service levels.

Tools to Simplify the Process

A structured Utilisation Tracker & Benchmark Sheet or similar spreadsheet makes it easy to log usage, calculate rates automatically, and compare results to targets. Even without telematics, disciplined monthly data entry provides actionable insights.

Tools to Simplify the Process

Fleet utilisation is more than a metric, it’s a lens on the financial health of your fleet. By measuring and acting on utilisation, organisations reduce costs, cut emissions, and improve service delivery. The earlier you start tracking, the sooner you can identify surplus vehicles and capture savings.

LeathFleet Advisory can help you build the strategy, policies, and data systems to get there

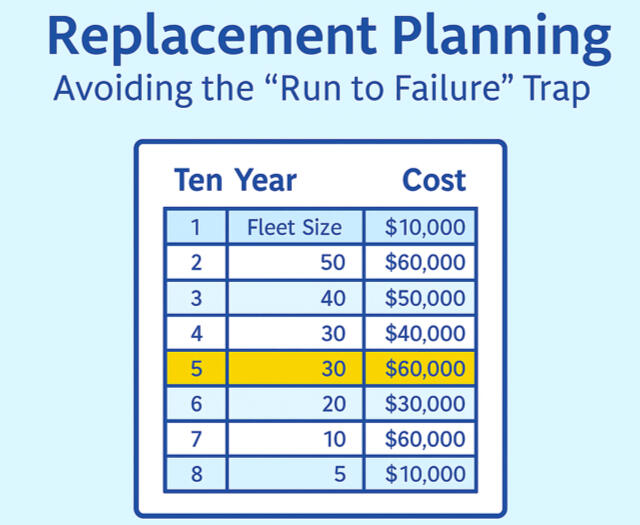

Fleet Replacement Planning: Avoiding the “Run to Failure” Trap

Why Fleet Replacement Planning Matters

Fleet replacement planning is the structured process of forecasting when each vehicle or piece of equipment should be retired and replaced. Instead of reacting to breakdowns or stretching assets until they fail, a replacement plan helps organisations control costs, reduce risk, and maintain service continuity.Many organisations, especially councils, utilities, and small to medium enterprises fall into the “run to failure” trap. Vehicles are kept long after their optimal service life. Maintenance costs climb, downtime increases, and budgets are hit with unpredictable capital demands. A well-designed fleet replacement plan avoids these surprises and provides a clear roadmap for both finance and operations teams.

The Real Cost of “Run to Failure”

It’s tempting to delay replacements when budgets are tight, but the numbers tell a different story:

Escalating maintenance expenses: As vehicles age, repairs become more frequent and costly.

Increased downtime: Unexpected failures disrupt field work, emergency response, and service delivery.

Safety and compliance risks: Older assets are more likely to fail inspections or breach chain-of-responsibility obligations.

Capital shocks: Eventually the vehicle still must be replaced, but now it’s urgent, and multiple replacements can cluster together, overwhelming budgets.

When all of these factors are considered, running assets to failure is often more expensive than replacing them on a planned schedule.

Key Principles of Effective Fleet Replacement Planning

Adopt a Whole-of-Life Cost MindsetThe foundation of smart planning is understanding total cost of ownership (TCO). Purchase price is only the beginning. Include:

Depreciation

Maintenance and repairs

Fuel or energy

Downtime costs (lost productivity, rentals or backups)

Resale value at disposal

When graphed over time, these costs form a “bathtub curve”: high early depreciation, a long period of stable expense, then rising maintenance costs. The ideal replacement point is where the sum of depreciation and operating costs is lowest.

Use Objective Replacement CriteriaTo avoid subjective decisions, score each asset against consistent criteria such as:

Age and kilometres/engine hours relative to industry benchmarks

Maintenance history and cost trends

Criticality - how essential the asset is to operations

Utilisation - is it being used enough to justify its place?

Fit for purpose - can it still safely and efficiently perform its tasks?

Assign weights to these factors and calculate a replacement score that drives capital forecasts.

Build a Multi-Year ForecastA 10-year replacement plan provides visibility for executives and finance teams. List every asset, its estimated replacement year, and projected cost (including CPI or expected market increases). Update the plan annually to reflect new data, disposal values, and operational changes.

Integrate with Capital BudgetingReplacement planning isn’t just an engineering exercise; it’s a financial strategy. Present the plan as a rolling capital program that smooths expenditure year to year and supports funding bids. Decision-makers can clearly see the impact of deferring or accelerating replacements.

Data and Tools You Can Use

Accurate planning depends on accurate data. At a minimum, maintain a fleet register with:

Acquisition date and cost

Current odometer or engine hours

Service and repair history

Residual value estimates

Modern telematics and maintenance systems can automate much of this. Even with spreadsheets, discipline in data entry delivers actionable insights.For smaller organisations, a structured Excel model such as a Fleet Replacement Planning Tool can calculate optimal timing, flag assets for review, and produce a summary report for management.

Tying in Fleet Utilisation

A written fleet replacement policy ensures consistency and protects against ad-hoc decisions. Elements to include:

Target replacement cycles by asset class

Required data for decision-making

Approval pathways and budget responsibilities

Rules for exceptions (e.g., specialist equipment)

Reporting requirements to executives or council

Clear governance avoids “special pleading” where individual departments push to keep aging vehicles without evidence.

Communicating the Plan

A strong plan is only valuable if stakeholders support it. Tailor your messaging:

Finance teams need to see predictable budgets and whole-of-life savings.

Operational managers need assurance that service levels won’t suffer.

Executives and councillors want risk reduction and transparency.

Provide visual dashboards or summary sheets showing cost trends, risk ratings, and the effect of deferring replacements.

Sustainability and Future Technology

Replacement planning is also the right time to consider alternative fuels and low-emission vehicles. By forecasting when assets will reach end of life, you can schedule pilot programs for electric or hybrid vehicles and coordinate infrastructure investments.

Steps to Get Started

Audit your fleet data. Confirm every asset’s age, usage, and maintenance costs.

Establish benchmarks. Use manufacturer guidelines or industry standards as starting points.

Create a scoring model. Weight age, utilisation, condition, and criticality.

Forecast capital needs. Develop a 5–10 year spreadsheet that shows timing and cost.

Draft a fleet replacement policy. Document decision rules and approval processes.

Review annually. Update data, re-score assets, and adjust the forecast.

Bringing It All Together

A proactive fleet replacement plan transforms how an organisation manages its vehicles and equipment. Instead of reacting to breakdowns, you’re managing the asset lifecycle, ensuring that capital is spent where it provides the most value, and maintaining safe, reliable service for staff and customers.By avoiding the “run to failure” trap, you reduce risk, protect budgets, and give your organisation a competitive advantage, whether you operate a dozen vehicles or several thousand.

LeathFleet Advisory can provide templates, a Fleet Replacement Planning Tool or develop an entire 10 year replacement plan.

Building a Fleet Policy that Works

Why Every Organisation Needs a Strong Fleet Policy

A fleet policy is the backbone of effective fleet management. It sets out how vehicles are purchased, maintained, and operated, and it defines the standards every driver, manager, and department must follow. Without a clear policy, organisations face higher costs, compliance gaps, and inconsistent practices across teams and locations.Whether you operate ten vehicles or several thousand, a well-crafted fleet policy provides clarity, accountability, and risk management. It’s the document that allows senior leaders to sleep at night, knowing the fleet is managed safely, legally, and cost-effectively.

The Purpose of a Fleet Policy

At its heart, a fleet policy answers three key questions:

Who is responsible? - from drivers to team leaders to executives.

What are the standards? - covering procurement, maintenance, safety, and environmental targets.

How is compliance maintained and measured? - including reporting requirements and consequences for non-compliance.

By formalising these answers, the policy becomes a living reference that keeps operations aligned and protects the organisation from regulatory and financial risk.

Benefits of a Well-Written Fleet Policy

At its heart, a fleet policy answers three key questions:

Cost control: Clear rules for purchasing, servicing, and replacing vehicles prevent ad-hoc decisions that inflate budgets.

Safety and compliance: Standardised inspection and maintenance schedules reduce incidents and meet legal obligations such as Chain of Responsibility requirements.

Operational consistency: Teams across regions or departments work to the same specifications, ensuring fair access to vehicles and reducing disputes.

Environmental responsibility: Policies can set targets for fuel efficiency or low-emission vehicles, supporting sustainability goals.

Key Sections of an Effective Fleet Policy

Use these headings as a template for your own document. Each section should include responsibilities, processes, and measurable standards.

Governance and RolesDefine the ownership of the fleet function—who authorises purchases, who oversees compliance, and how reporting flows to senior management or council. This section should include a hierarchy of accountability: fleet manager or coordinator, regional supervisors, and drivers.

Procurement and AcquisitionDetail the process for specifying and acquiring vehicles, including approval steps, competitive tendering, and total-cost-of-ownership considerations. Outline preferred suppliers or purchasing panels if applicable.

Vehicle Specifications and StandardisationSet the minimum safety and fit-out requirements for each class of vehicle. Standardised specifications reduce complexity, simplify maintenance, and allow bulk purchasing advantages.

Utilisation and PoolingExplain how vehicle utilisation will be monitored through odometer readings, engine hours, or telematics, and the benchmarks for assessing under-use. Include rules for pooling or sharing vehicles to increase efficiency.

Maintenance and ServicingSpecify service intervals, authorised workshops, and record-keeping requirements. Include how unscheduled repairs are approved and who bears responsibility for costs.

Safety, Compliance, and Chain of ResponsibilityOutline obligations for daily pre-start checks, incident reporting, and driver responsibilities under heavy vehicle laws or equivalent regulations. Include fatigue management and driver licence verification.

Fuel and EmissionsDescribe preferred fuel types, efficiency targets, and any low-emission or electric vehicle initiatives. If you plan to transition to alternative fuels, capture those goals here.

Replacement and DisposalSummarise your fleet replacement planning method: the scoring model, funding approach, and disposal process (including resale, trade-in, or auction).

Insurance and Risk ManagementList insurance coverage, accident reporting procedures, and escalation steps for major incidents.

Driver Responsibilities and ConductProvide a clear code of conduct covering safe driving, mobile phone use, alcohol and drug policies, and disciplinary actions for breaches.

Drafting the Fleet Policy: Practical Steps

Audit Current Practices - Review existing documents, service schedules, and regional procedures. Identify gaps and conflicting standards.

Engage Stakeholders - Involve representatives from operations, finance, WHS, and senior management early. Their input ensures buy-in and smooth adoption.

Benchmark and Research - Refer to industry guidelines, manufacturer standards, and government fleet frameworks for best-practice targets.

Write in Plain Language - Policies fail when staff cannot understand them. Use clear, concise wording and avoid unnecessary jargon.

Provide Supporting Tools - Attach checklists, sample forms, and links to digital reporting systems so staff can act on the policy without guesswork.

Approval and Communication - Present the draft to executives or the governing body for formal sign-off. Roll out with briefings, email summaries, and training sessions.

Review Regularly - Set a review cycle, typically every two or three years, or sooner if major legislation or fleet technology changes.

Turning Policy Into Practice

A fleet policy is only effective if staff use it every day. Consider:

Induction training for new drivers and managers.

Digital access, publish the policy on the intranet or fleet portal so it’s easy to find.

Compliance monitoring through dashboards or quarterly reports.

Performance indicators such as maintenance adherence rates, utilisation percentages, and incident statistics.

Connecting Policy to Broader Fleet Strategy

Your fleet policy should not exist in isolation. It underpins the wider fleet management strategy, including 10-year replacement plans, whole-of-life cost modelling, and utilisation tracking. When these documents align, you create a governance framework that survives leadership changes and funding cycles.

Getting Started Today

If you’re starting from scratch, begin with a simple template and expand as your organisation’s needs grow. Key actions:

Create a one-page policy outline listing each major section.

Gather existing data on vehicles, maintenance, and costs.

Schedule a cross-department workshop to identify priorities and risks.

Set a timeline for drafting, consultation, and approval.

Bringing It All Together

A fleet policy that works is more than a compliance document, it’s a living guide that drives cost savings, safety improvements, and environmental progress. By clearly defining responsibilities, setting measurable standards, and integrating with long-term fleet strategy, you create a foundation for efficient operations and predictable budgets.Whether you manage a small business fleet or a nationwide government operation, investing time in a comprehensive, well-structured fleet policy is one of the most powerful steps you can take to protect your people, your assets, and your bottom line.